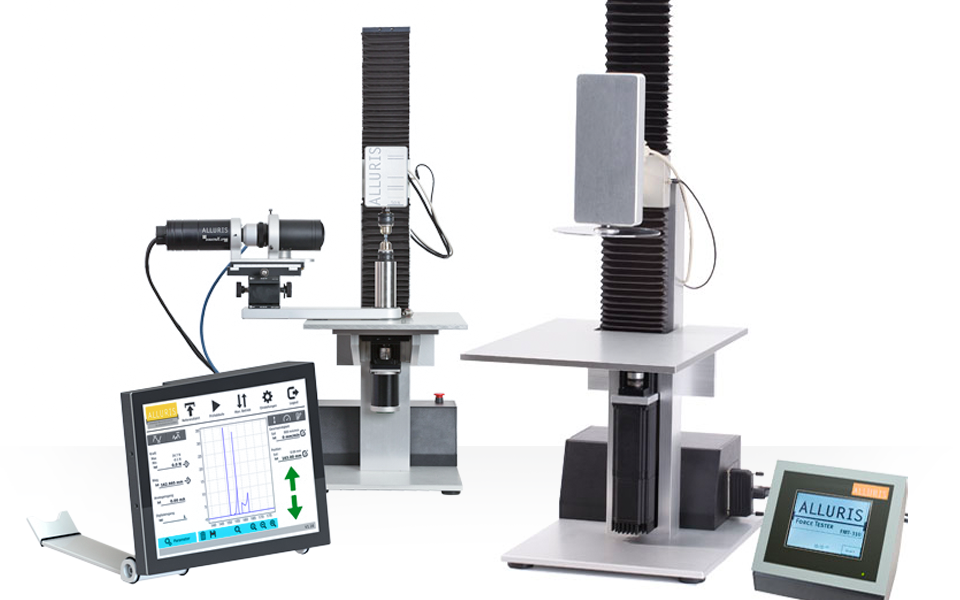

The universal testing apparatus is essential for evaluating the mechanical characteristics of materials in a variety of sectors. All of the information you need to know about universal testing machines is that they test the elasticity, strength, and durability of materials by applying forces like tension, compression, or bending. These machines are widely employed in manufacturing, research, and construction to guarantee that items fulfill safety and quality requirements. The precision and adaptability of the universal testing machine makes them essential instruments for quality control and material testing.

Let us delve into five key aspects you should know about universal testing machines.

Versatility in testing

A universal testing machine can perform various types of tests, including tensile, compression, bending, and shear tests. It can be used on a wide range of materials, such as metals, plastics, textiles, rubber, and wood. This versatility allows industries to test multiple materials with a single machine, saving time and resources.

Precise and accurate results

The primary advantage of a universal testing machine is its ability to deliver highly precise and accurate measurements. It assesses properties such as tensile strength, elongation, modulus of elasticity, and more. This accuracy is essential for determining whether materials meet industry standards and are safe for use in products or structures.

Ease of operation and automation

Modern universal testing machines are equipped with user-friendly interfaces, making them easy to operate even for those with minimal technical experience. Many machines come with advanced software that automates the testing process and provides detailed data analysis. This feature allows operators to quickly set up tests and receive real-time results, improving efficiency in the lab or production line.

Durability and long-term reliability

Universal testing machines are built to last, constructed from high-quality materials that can withstand constant use. Their sturdy design ensures long-term reliability, making them a valuable investment for companies. Regular maintenance and calibration also contribute to their prolonged lifespan and consistent performance.

Widespread application across industries

Universal testing machines are used in various industries, including aerospace, automotive, construction, and education. They are crucial in quality control, research and development, and material certification. Engineers, researchers, and educators rely on these machines to understand how materials behave under different conditions and ensure that they meet safety and regulatory requirements.

To conclude

Universal testing machines are essential for ensuring material quality and safety. Their versatility, precision, ease of use, and durability make them invaluable tools for many industries, contributing to the development of safe and reliable products.